Trade ins. Sell the old geep to GE for scrap price, GE discounted its scrap worth and kept the trucks as a base for their motors vs paying for new ones.

You can see ALCO FB-2s under SOO GP30s too.

CSX EMD trucks on U boats?

First unread post • 4 posts

• Page 1 of 1

Re: CSX EMD trucks on U boats?

Anthony Wood

Audio Engineer - Searchlight Simulations

Audio Engineer - Searchlight Simulations

-

BNSFdude - Posts: 2721

- Joined: Tue Nov 29, 2011 1:46 am

Re: CSX EMD trucks on U boats?

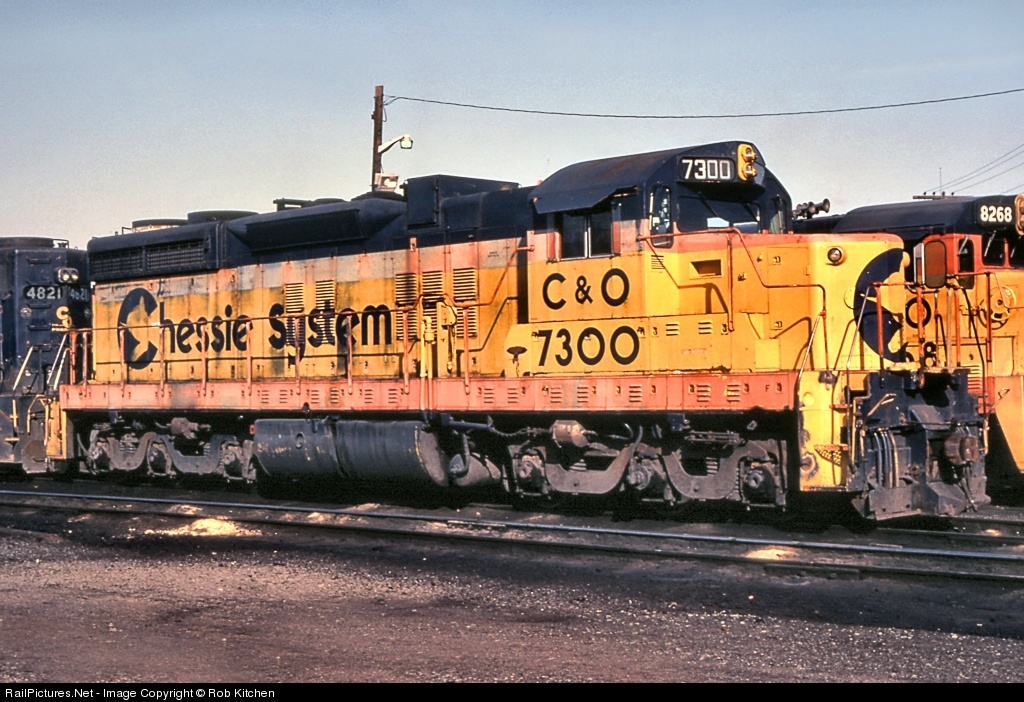

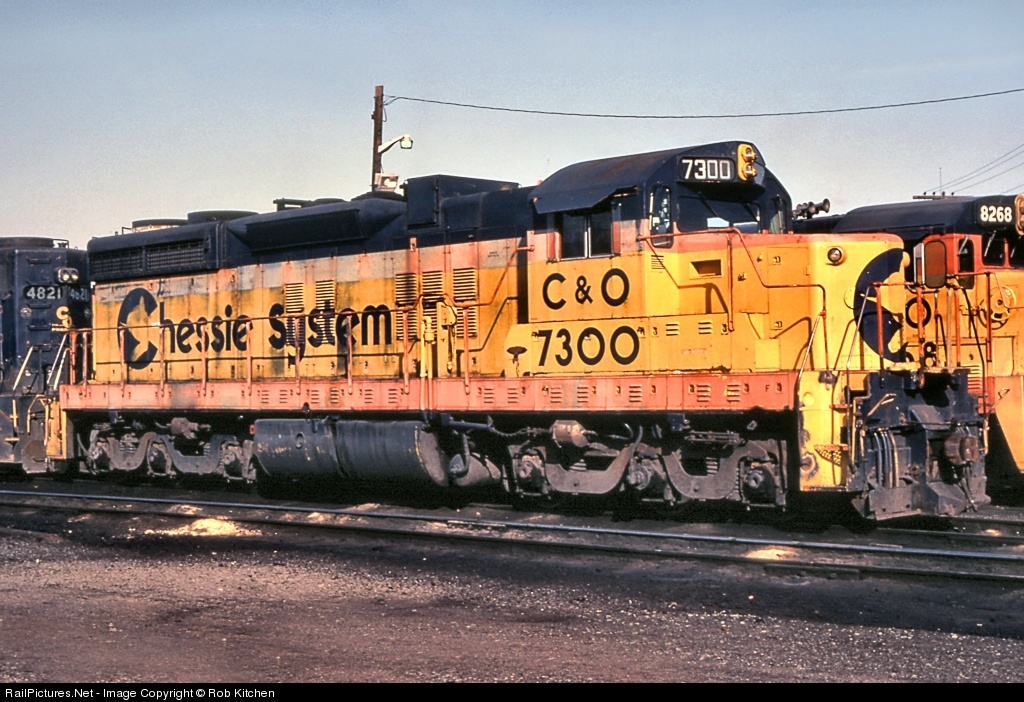

Or even stranger, ALCo RSD trucks under a C&O EMD SD18, which by itself is quite a rare engine.

/

/

Notice the home made "smoke splitters/spark arrestors (?)" over the stacks.

Or were they simple devices to keep rain out of the exhaust? I believe US RR's never shut their engines down when idling/laying over the night/next shift.

/

/Notice the home made "smoke splitters/spark arrestors (?)" over the stacks.

Or were they simple devices to keep rain out of the exhaust? I believe US RR's never shut their engines down when idling/laying over the night/next shift.

Edwin "Kanawha"

The Chessie, the train that never was ... (6000 hp Baldwin-Westinghouse steam turbine electric)

The Chessie, the train that never was ... (6000 hp Baldwin-Westinghouse steam turbine electric)

-

_o_OOOO_oo-Kanawha - Posts: 3231

- Joined: Mon Nov 14, 2011 2:12 pm

Re: CSX EMD trucks on U boats?

The trucks are not universal...swapping them requires some adaptation. However, the cost of used trucks vs. new ones was very appealing to a number of southern railroads. Southern Ry. used Alco trucks under a number of its GP35's.

You do not have the required permissions to view the files attached to this post.

-

harryadkins - Posts: 3128

- Joined: Sun Aug 23, 2009 8:01 am

- Location: South Carolina, USA

Re: CSX EMD trucks on U boats?

I think it was not so much the trucks, but rather the traction motors. If the bolsters fitted the kingpins and the traction motor air conducts were not too far off, it was relatively simple.

Only some cables, air lines, sand hoses and handbrake chain needed to be fitted and the locomotive was ready for service.

ALCo, Baldwin, Lima, Hamilton, F-M, used GE or Westinghouse traction motors, which had a good and proven reputation and long lifespan. EMD's were essentially throw aways, much like the GM cars, that were made to have only a certain economic/service live.

Early FT, F3 trucks were often traded in and re-used as well, also under GE units. But that was perhaps as the locomotives themselves were obsolete or worn out, while their Blomberg trucks and traction motors still had a few years in them. Obsolete road switchers from minority makers like those mentioned above were also trade in candidates, but often RR's re-engined them instead, so they could be used in subordinate services for a couple of more years.

I don't know if the economics of leasing vs. owning locomotives played a role in those days.

So you see many early 60's hood units like GP30/35 and U25/28 on traded in trucks from obslote cab units.

Western Pacific stressed it a bit too far, GE had to shoehorn their larger traction motors and axle boxes into the too narrow sideframes of the traded in FT Blomberg trucks under WP's U30B's. Also because WP ordered their U30B's with maximum ballast, they had a bad reputation both with shop and track crews, and probably with the engines crews and HQ brass as well after a while. None were ever run by UP after the WP was absorbed in 1982.

Only some cables, air lines, sand hoses and handbrake chain needed to be fitted and the locomotive was ready for service.

ALCo, Baldwin, Lima, Hamilton, F-M, used GE or Westinghouse traction motors, which had a good and proven reputation and long lifespan. EMD's were essentially throw aways, much like the GM cars, that were made to have only a certain economic/service live.

Early FT, F3 trucks were often traded in and re-used as well, also under GE units. But that was perhaps as the locomotives themselves were obsolete or worn out, while their Blomberg trucks and traction motors still had a few years in them. Obsolete road switchers from minority makers like those mentioned above were also trade in candidates, but often RR's re-engined them instead, so they could be used in subordinate services for a couple of more years.

I don't know if the economics of leasing vs. owning locomotives played a role in those days.

So you see many early 60's hood units like GP30/35 and U25/28 on traded in trucks from obslote cab units.

Western Pacific stressed it a bit too far, GE had to shoehorn their larger traction motors and axle boxes into the too narrow sideframes of the traded in FT Blomberg trucks under WP's U30B's. Also because WP ordered their U30B's with maximum ballast, they had a bad reputation both with shop and track crews, and probably with the engines crews and HQ brass as well after a while. None were ever run by UP after the WP was absorbed in 1982.

Edwin "Kanawha"

The Chessie, the train that never was ... (6000 hp Baldwin-Westinghouse steam turbine electric)

The Chessie, the train that never was ... (6000 hp Baldwin-Westinghouse steam turbine electric)

-

_o_OOOO_oo-Kanawha - Posts: 3231

- Joined: Mon Nov 14, 2011 2:12 pm

4 posts

• Page 1 of 1

Who is online

Users browsing this forum: No registered users and 5 guests